How to Install Solar Pumping System?

Xrise New Energy Technology Co., Ltd. in order to standardize the construction, installation, commissioning and acceptance of photovoltaic water pump system, to achieve advanced technology, safety and application, economic and reasonable, long-term reliability, to ensure quality, the formulation of this code.

This specification applies to the construction, installation, commissioning and acceptance of new, rebuilt and expanded photovoltaic water pump systems.

The scope of construction, installation and commissioning includes all civil works and equipment installation works in the photovoltaic water pump system.

Electrical engineering, equipment commissioning, fire protection engineering and lightning protection grounding, etc.

Construction personnel should be familiar with this code and the current safety technical standards and product technical documents before construction, and

Only after passing the safety examination can they be allowed to work.

In the construction of the photovoltaic water pump system, in addition to this specification, it should also meet the current relevant national standards.

Solar pumping system parts

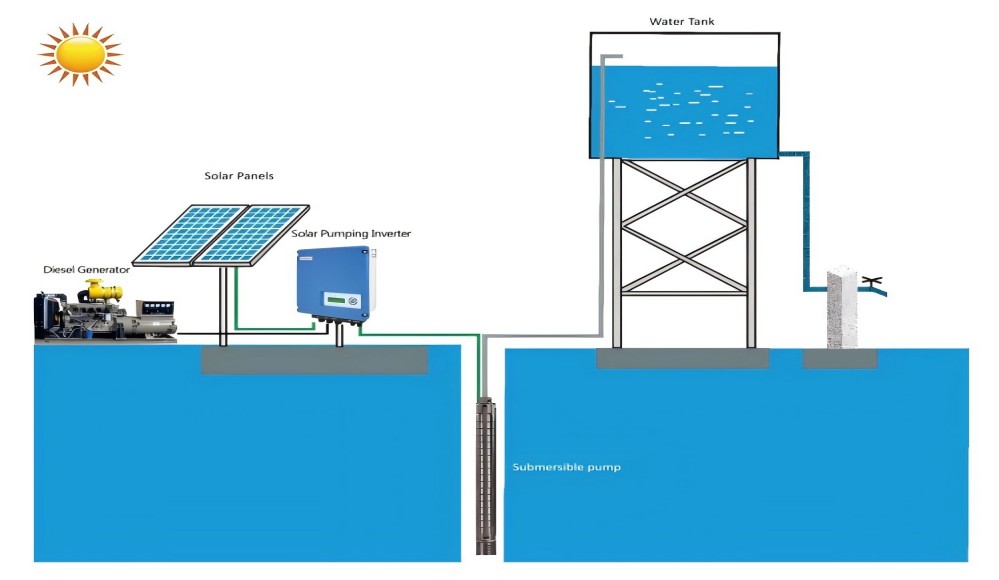

2.0.1 Solar pumping system (referred to as photovoltaic pumping system) PV pumping system

Consists of solar cell components/arrays, cables, control units (e.g. controllers, inverters), motors, pumps and a device consisting of pipes and valves that convert solar energy into electricity to pump water.

2.0.2 Module (solar cell module) module (solar cell module):

Refers to a package and internal connection, can provide direct current output alone, the smallest indivisible solar cell

A combination device. Also known as photovoltaic modules.

Array (solar cell array) array (solar cell array):

A number of solar cell components or solar panels are mechanically and electrically assembled together in a certain manner

And there is a fixed support structure composed of DC power generation unit, foundation, sun tracker, temperature controller, etc

Similar parts are not included in the phalanx. Also known as the photovoltaic array.

Bus box Combiner:

In the solar photovoltaic power generation system, a certain number of photovoltaic modules with the same specifications are connected in series to form a

Each photovoltaic series, and then a number of photovoltaic series parallel confluence after access device.

Solar pumping inverter:

The utility model converts the direct current emitted by a solar cell into a three-phase alternating current with adjustable amplitude and frequency and drives the third phase Phase AC pump motor device.

PV support bracket PV support bracket:

It is a special bracket designed for placing, installing and fixing solar panels in the solar photovoltaic power generation system.

Basic regulations

3.0.1 Requirements before commencement:

1. Before the construction of the project starts, the construction unit shall obtain the corresponding approval procedures.

2. The qualification of the construction unit, the qualification of special operators, construction machinery, construction materials, measuring instruments, etc., have been submitted for examination

Check it out.

3. The construction drawings have been reviewed.

4. The construction unit has completed the arrangement of temporary construction facilities according to the requirements of the construction general layout plan.

5. Conditions should be met for engineering positioning measurement.

3.0.2 The specifications of the equipment and materials shall meet the design requirements, and unidentified and unqualified equipment shall not be used in the project

Materials.

3.0.3 Unpack the equipment and check that the certificates, manuals, accessories, and spare parts are complete.

3.0.4 The transportation and storage of equipment and equipment shall meet the requirements of this Code, and when the product has special requirements, it shall meet the production

Special provisions for product requirements.

3.0.5 For concealed works, intermediate inspection and acceptance records must be made jointly with relevant units before concealment.

3.0.6 Complete construction records and construction test records.

Building Projects

4.1.1 The construction unit shall, in accordance with the relevant provisions of the Regulations on the Supervision of the Implementation of Mandatory Standards for Project Construction, implement the Regulations

Mandatory provisions on construction standards.

4.1.2 Foundation pit engineering shall meet GB 50202 Code for Acceptance of Construction Quality of Building Foundation and Building foundation pit support

Specification "JGJ120," Technical Code for Building Pile Foundation "JGJ94 requirements.

4.1.3 When steel bars and steels enter the market, their varieties, grades, specifications and quantities shall meet the design requirements. And by country current

The quality of specimens extracted for mechanical property inspection shall meet the requirements of relevant standards.

4.1.4 When the cement enters the market, it shall be inspected for its variety, grade, package or bulk bin number, date of delivery, etc., and shall

Retest its strength, stability and other necessary performance indicators, and its quality should meet the current national standards

The regulations of...

4.1.5 Formwork and its support shall be supplied according to the form of engineering structure, load size, type of foundation soil, construction equipment and materials

The design and production should be carried out under such conditions. The formwork and its support should have sufficient bearing capacity, stiffness and stability.

It can reliably withstand the weight, side pressure and construction load of poured concrete.

4.1.6 Concrete shall be mixed strictly in accordance with the laboratory mix ratio, and the concrete strength test shall comply with the "Concrete Strength"

Inspection and Evaluation Standard GB 50107 relevant provisions; Such as concrete admixture, related quality and application

The technology should conform to the current national standard "Concrete admixture" GB 8076, "Concrete admixture application technology.

Specification "GB 50119 and other provisions.

4.1.7 Concrete maintenance shall take effective measures in a timely manner according to the construction technical plan, and shall comply with the following provisions:

1. The concrete should be covered and moisturized within 12 hours after pouring; Watering frequency should be maintained

The concrete is wet; The water used for curing concrete should be the same as that used for mixing.

2. Concrete watering and curing time: the use of Portland cement, ordinary Portland cement or slag Portland cement

Mixed concrete, not less than 7 days; For concrete with retarding admixtures or impermeability requirements, no

Less than 14 days.

3. Concrete in winter should be covered with plastic film and heat preservation maintenance.

4. All surfaces of the concrete covered with plastic film should be covered tightly and should be kept inside the plastic sheet

Condensate water.

4.1.8 After the pouring of cast-in-place concrete foundation, if settlement observation is required, settlement observation signs shall be set up in time

Good settlement observation record.

Support foundation

4.2.1 The construction of cast-in-place concrete support foundation shall comply with the following provisions:

1. The concrete should be cleaned before pouring. The acceptance of the foundation groove should be carried out first, and the axis, the size of the foundation pit and the elevation of the foundation should be

Meet the design requirements. Foundation pit floating soil, water, debris

8

2. The cushion concrete should be poured immediately after checking the pit groove.

3. The foundation elevation, axis and formwork installation should be carefully checked and self-checked before the concrete pouring of the support foundation

Inspection records, the reinforcement concealed works should be accepted, embedded parts should be installed in accordance with the design drawings.

4. After the foundation mold removal, the supervision (construction) unit and the construction unit shall check the appearance quality and size deviation.

Records shall be made, and defects shall be dealt with in a timely manner according to acceptance standards.

5. The deviation between the position of the embedded part and the design drawing should not exceed ±5mm, and the exposed metal embedded part should be anti-corrosion and anti-rust

Deal.

6. When concrete is poured in the same support foundation, the interval time of concrete pouring should not exceed 2 hours; More than 2 small

When, it should be treated in accordance with the construction joint.

7. Effective maintenance measures should be taken in time after concrete pouring is completed.

8. Before welding the top embedded parts with the steel support legs, the foundation concrete curing should reach 100% strength.

4.3.2 The construction of static pressure pile foundation shall comply with the following provisions:

1. The pile in place should be kept upright, so that the axis of the jack, pile joint and pile press hole coincide, and should not be eccentric and pressurized. Static pressure

The head of the prefabricated pile shall be fitted with a steel pile cap.

2. In the process of pile pressing, check the pressure, pile perpendicularity and pressing depth, and the deviation of pile position plane shall not exceed ±10mm.

The deviation of pile section perpendicularity shall not be greater than 1% of pile section length.

3. Pile pressing should be carried out continuously, and the interval between the same pile should not exceed 30min. The pile pressing speed should not be exceeded

2m/min.

4. The outer part of the steel pipe should be wrapped with geomembrane, and the inner part of the steel pipe should be anticorrosive by grouting with grain filling.