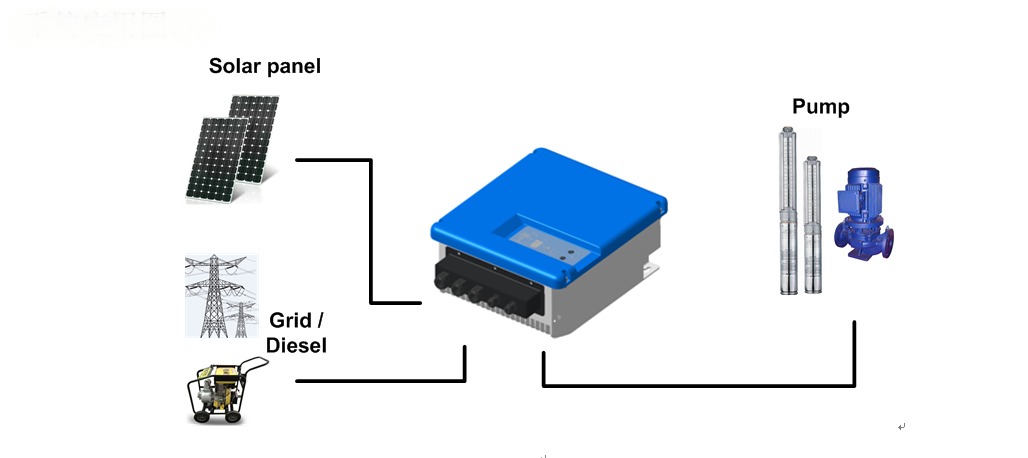

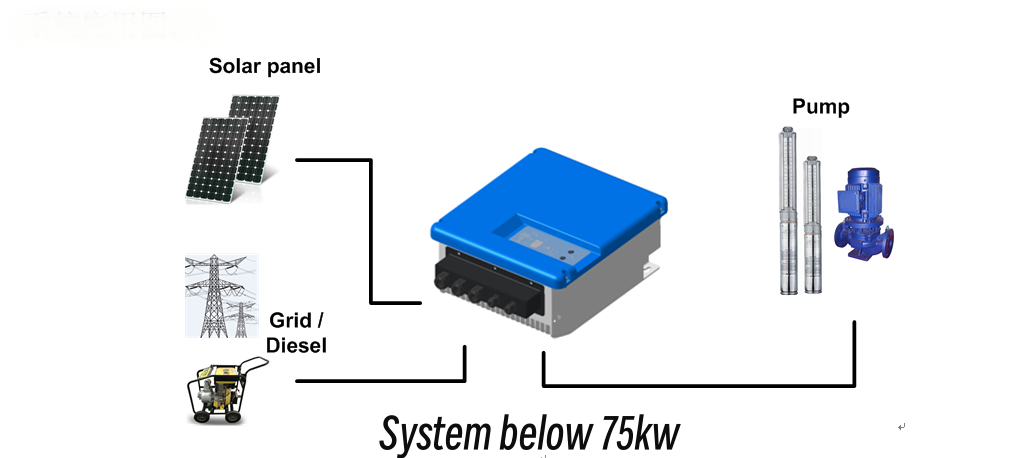

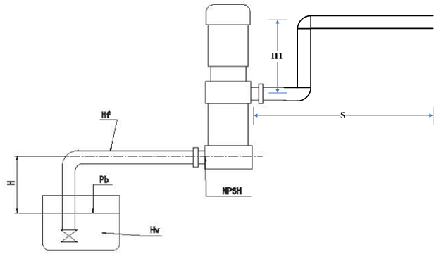

Solar water pump system application diagram

Photovoltaic pump system is a complex pump application system, but also a complex engineering application. There are many factors to consider when configuring a system. The main reason is the difference between the utility pump system and the photovoltaic pump system.

Since solar energy is related to sunshine intensity, the working process of the photovoltaic pump system is: standby → start → light load → full load → light load → Stop → standby → close. The water yield of the photovoltaic pump system: water yield → small water yield → small water yield → no water yield. The water output of the pump in the mains pump system: the system is always rated water output.

Photovoltaic pump system and the mains pump system in the pump selection is very different, the same system lift, the lift of the photovoltaic pump system needs to be greater than the mains pump system, so that the photovoltaic pump system in the weak sunlight when the system can also be water, as far as possible to extend the working time of the photovoltaic pump system.

How to configure the photovoltaic water pump system?

Configuration principle

Step1: Determine the daily average hourly flow rate based on 1/T times the daily water demand (T: the system's daily full load working time, such as Hefei, T=5);

Step2: Select the rated flow rate of the pump according to the daily average hourly flow rate of 1.0 times;

Step3: The design head of the system is about 1.1-1.2 times the minimum head of the system;

Step4: The above three steps to determine the pump model, according to the pump power to choose the same power of photovoltaic pump inverter;

Step5: The peak power of the system input photovoltaic module is about 1.2-1.5 times the rated power of the pump motor.

Note: The system configuration is based on the water demand as the starting point, the first step to select the pump, the second part to select the photovoltaic pump inverter, the third step to select the photovoltaic module (photovoltaic cell).

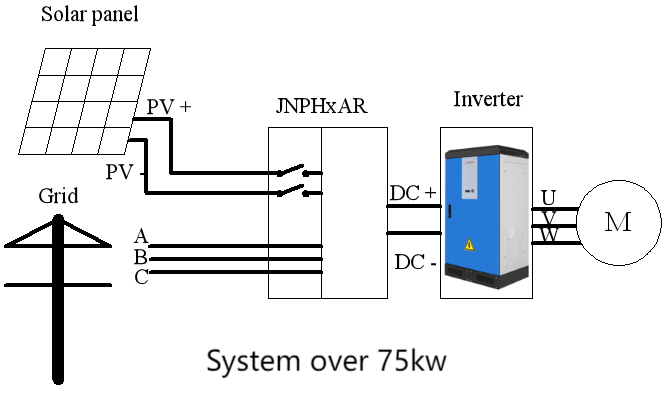

Step6: If there is a power grid/diesel engine input demand, there is no 24-hour water demand, the system below 55kW uses JNP2K2L-SE-V5 system, JNP7K5H-V5 system, JNP18K5H-V5 system,JNP55KH-V5 system, and the system above 75kW uses AC-DC distribution box products +JNP132KH series

Configure input information

Submersible pump

Installation location and use of photovoltaic water pump system

Water source type

Required daily water consumption

Pipe type and inside diameter Dn

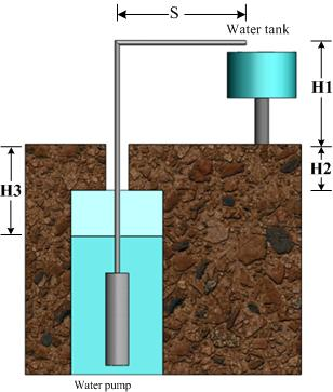

Distance from ground to outlet H1

The distance from the static water level to the ground is H2

The distance from the lowest water level of the water source (the dynamic water level of the water source, if it cannot be provided about the outlet position of the pump) to the ground H3

Horizontal distance from water source to pipe outlet S

Refer to "Technical Specification for Low-pressure pipeline Irrigation Engineering in Farmland" GB/T 20203-2006 for head calculation

Surface pump

Installation location and use of photovoltaic water pump system

Water source type

Required daily water consumption

Pipe type and inside diameter Dn

Distance from pump inlet to water source dynamic water level H

The vertical distance between pump outlet and pipe outlet is H1

Vertical distance from pump outlet to pipe outlet S

Refer to "Technical Specification for Low-pressure pipeline Irrigation Engineering in Farmland" GB/T 20203-2006 for head calculation

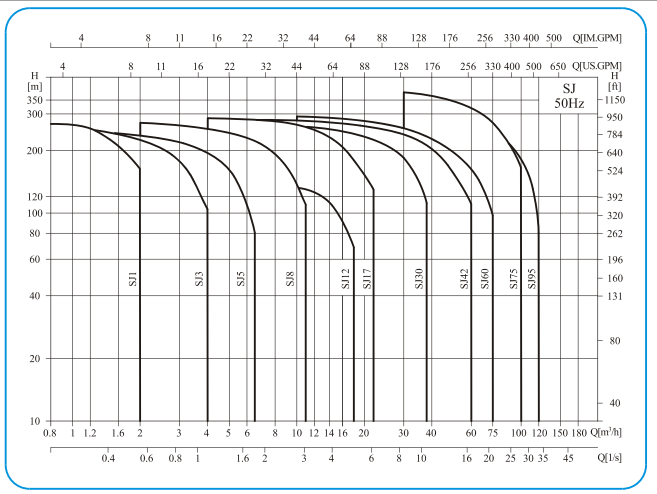

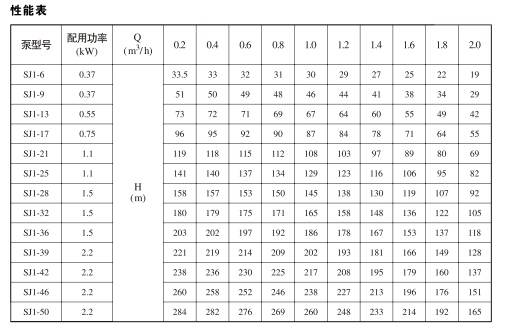

Pump selection

According to the installation site and water source of the pump to determine the type of pump, submersible pump or surface pump, if the surface pump needs to consider the suction of the pump, if the pump does not have a self-priming function, the pump inlet needs to add a bottom valve; Suction generally not more than 5 meters, specific reference to the specifications of the pump;

Pump rated flow rate determination: pump rated flow rate = system daily water demand x (0.2);

Pump rated head determination: pump rated head = (H1 + H3 + S x 0.07) x (1.1~1.2);

For different photovoltaic pump system application needs, you can appropriately reduce these indicators, such as a domestic water project, the original mains drive pump, working 2 hours a day, 18m head, flow 8m3/h, now replaced by photovoltaic pump system, can completely reduce these indicators, because the photovoltaic pump system is relatively long working time. The guiding idea is that the photovoltaic pump system tries to use time in exchange for flow under the premise of meeting the system head;

For a long time flow must reach a certain value, the photovoltaic pump system and the utility pump system compared with the inherent shortcomings, if you want to achieve this index, is bound to increase the cost of the system. Of course, there is a potential problem in the actual project, often the customer's first proposed flow and head, is in accordance with the mains drive pump, pump full load operation of the case obtained indicators, so in the early stage of system configuration we need to identify treatment, carefully measured.

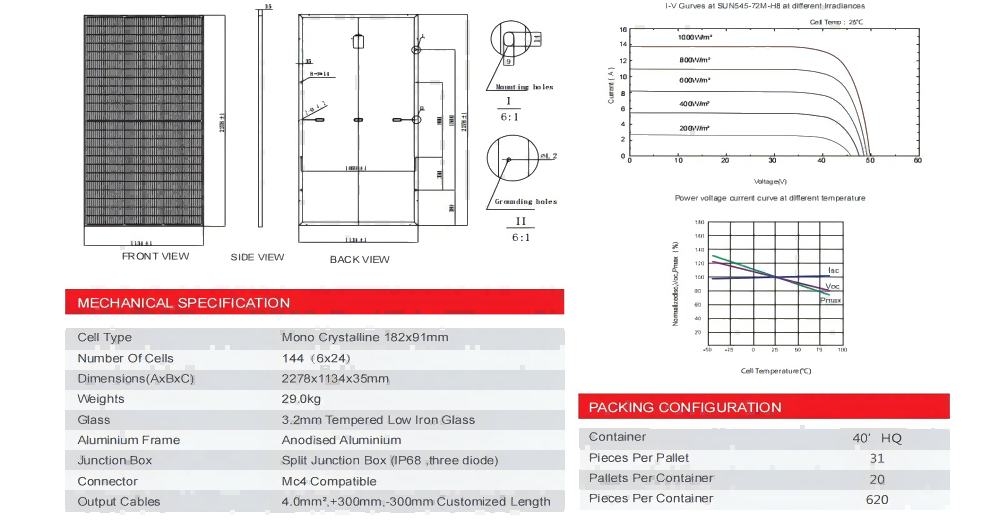

Pv module selection

Selection principle

1) The photovoltaic module is the photovoltaic pump system optional solar module, the maximum output power after the series (Vmp x Imp) is about 1.2 to 1.5 times the rated power of the pump motor;

2) The maximum output open circuit voltage Voc of the photovoltaic module after the series is less than the maximum input voltage of our photovoltaic water pump inverter;

3) The maximum power point voltage Vmp of the photovoltaic module after the series is within the recommended MPPT voltage range of our photovoltaic water pump inverter.

Hybrid photovoltaic water pump system configuration Background:

There are many factors that affect the configuration of photovoltaic systems, considering the fluctuation of grid voltage, external ambient temperature, and solar radiation. Photovoltaic modules as the temperature increases the voltage will decrease, for example: 72 components, 25 degrees Celsius, Vmp=39V, 50 degrees Celsius, Vmp=35.9V. At 60 degrees Celsius, Vmp=34.7V.

For the three-phase 380V/50Hz system, the system operating voltage is 540V, the system Vmp < 600V, such as 15 series 72 pieces of photovoltaic module configuration, the system efficiency is higher.

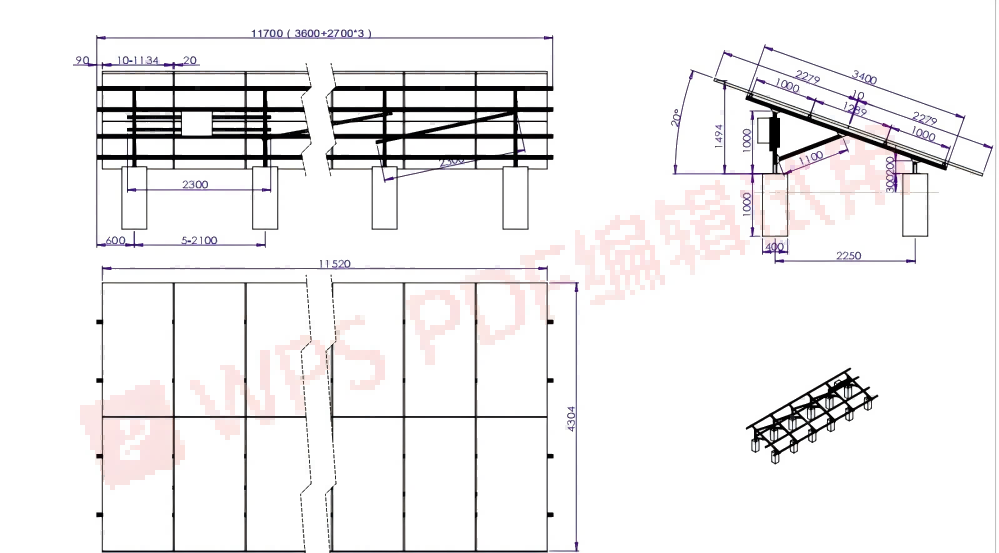

Solar mounting structure selection

System installation principles

Refer to the user manual to the photovoltaic pump inverter vertical wall hanging, and require no direct sunlight;

Photovoltaic modules, photovoltaic pump inverters and water sources as close as possible, can improve conversion efficiency and easy maintenance;

When laying pipes and connecting with pumps, professional and technical personnel are required to guide and operate;

A check valve needs to be added in the pipeline;

Valves should be added in the piping system design to adjust the flow and head of the system site;

After the system is installed, you need to refer to our photovoltaic pump inverter user manual for trial operation, and real-time detection of circuit system and pipeline system performance to ensure system reliability.